Hmt seal systems are customized for each specific tank with a variety of configurations component sizes and material options available to handle any application and stored product.

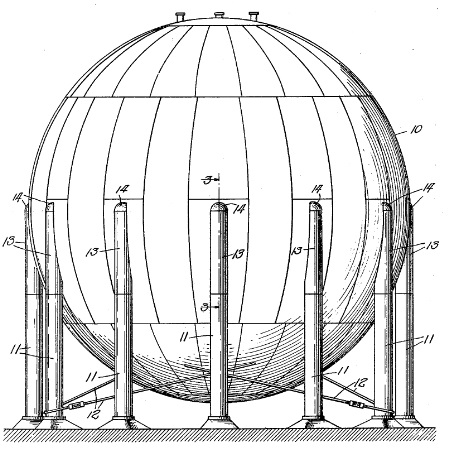

Horton floating roof.

16 02 2007 sonal equrments for horton type s pontoon float fora general desrpton and nora accessories soe atypical pln andcrse secion of ot ste shownin figures 01a and 0.

Operating under a short deadline the engineers succeeded in designing an original horton model.

Hmt offers a full line of primary and secondary seals for both internal and external floating roof tanks.

Here it is advisable to start with an integrated double seal.

This threatened to knock the company out of its most profitable peacetime line at precisely the wrong moment.

Horton type 5 pontoon floating roofs detail requirements red book number.

It is the most widely used seal design on floating roof tanks and has been used on tanks ranging from 6 0m to 107 0m in diameter storing crude oil refined products engineering details the weighted pantograph system ensures that the sealing ring is held in constant contact with the tank shell.

Hmt seals are well known as leading the industry in design quality craftsmanship durability and non.

Trees issued a challenge to his engineers to develop an improved floating roof technology free of wiggins patent.

In this case the third seal only need the height of a former separate secondary seal.